On the way from the idea to the finished product on the market, there is no way around the production of a functional sample. This can be used to carry out tests and adapt the software to the hardware.

With es:make, we offer you a simple and flexible solution for the production of a prototype. Our team, our processes and our laboratory equipment ensure that every step of the prototyping process is carried out reliably.

Solder paste printing: Application of solder paste to the PCB to create an optimum basis for component assembly.

SMT (Surface-Mount Technology) assembly: Automatic placement of surface-mounted components with maximum precision and speed.

THT (Through-Hole Technology) assembly: Manual or automatic placement of through-hole mounted components, depending on the requirements and complexity of the project.

Reflow soldering: Carrying out the reflow soldering process to securely fix the SMT components and ensure a stable electrical connection.

Hand soldering: Manual soldering of components and connections that cannot be soldered automatically in order to fulfil special requirements.

Housing 3D printing: Production of the enclosure using 3D printing to offer customised and functional enclosure solutions.

Cabling and module integration: Careful cabling and integration of all modules to ensure a complete and ready-to-use prototype.

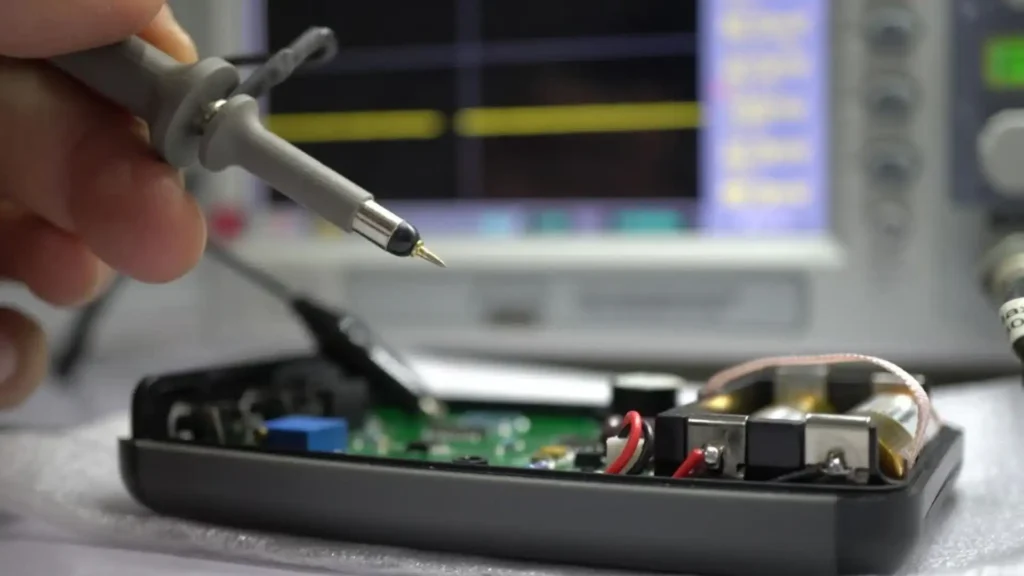

Testing the prototype:

Soldering and assembly

Electronic components, printed circuit boards

Testing prototypes

es:scope® is a registered trademark of es:saar GmbH. All Rights reserved.