The path from idea to market with an electronic product is not easy. High technical and regulatory requirements have to be met under cost and time pressure. There are strong interactions between the requirements right from the start. Customised solutions are required, the adaptation of which becomes increasingly expensive and complex as development progresses. The effort involved is high.

es:serve is our solution that allows you to outsource development tasks. By outsourcing these development processes, you can concentrate on your core competences and rely on the fact that the development is carried out carefully. We reduce the cost of development, making it more affordable and accessible.

Preparation

Concept

Hardware

Prototyping

Software

Validation

Production

In-Life

Detailed description of the functional requirements:

If pre-development is required: Research on technologies, technology assessment, feasibility studies, preliminary investigations

Pre-development

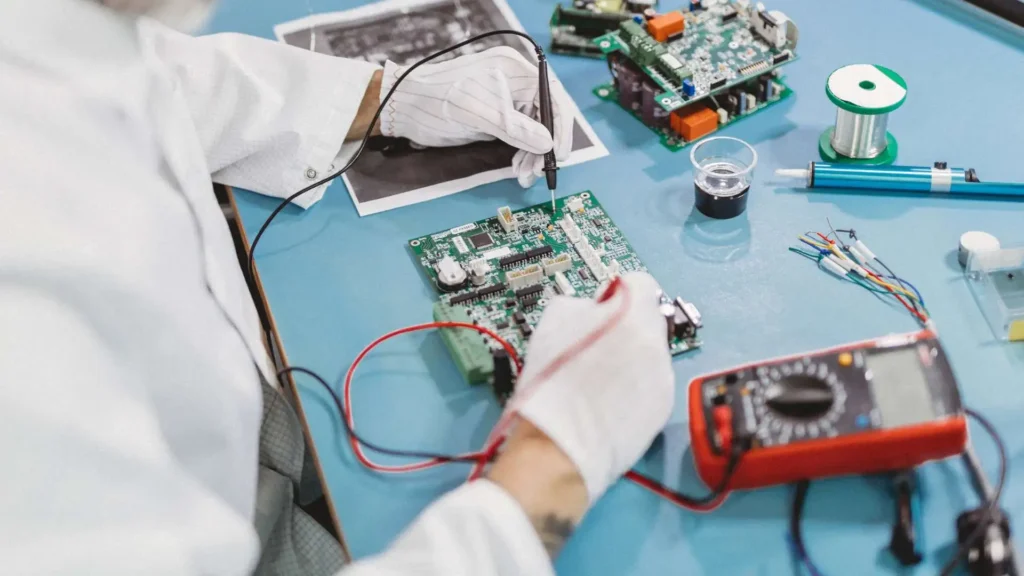

Circuit diagram development

Layout development (PCB design)

If design is required: Design of the mechanical components and the housing, simulation if necessary

Procurement

Production of the prototype

Pre-development

Implementation

Low-Level:

Mid-Level:

Application Level:

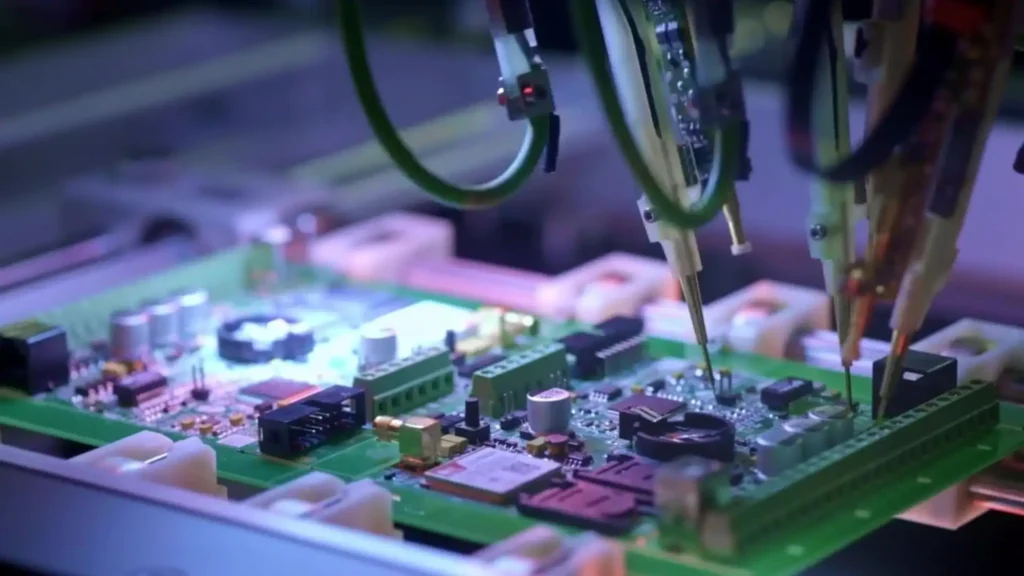

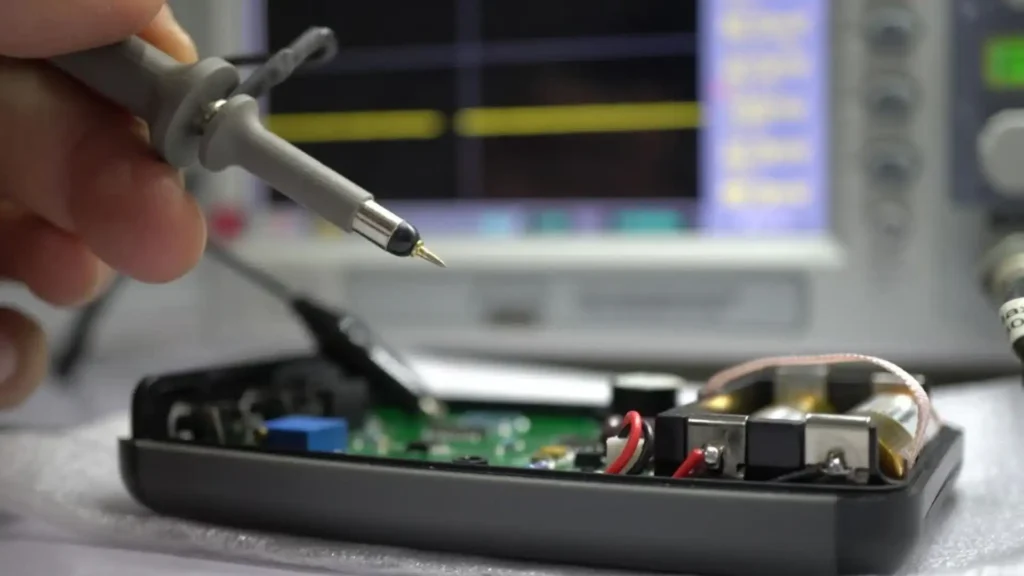

System validation

Testing of the entire system to ensure that all requirements and specifications are met. Checking the performance and reliability of the system in the real operating environment and under real operating conditions. Identification of faults and deviations from the desired behaviour.

System calibration

Adjustment and fine tuning of the system components. Calibration of sensors, actuators, filters and controllers to ensure measurement accuracy and system performance.

Preparation

Production

Retail

Series production support

Obsolescence management

Design Refresh

es:scope® is a registered trademark of es:saar GmbH. All Rights reserved.